We reserve the right to make design changes in the interest of technical progress.

www.elite.es

DOWNLOADS

SPECIFICATIONS

VIDEOS

Sharpening machine for interchangeable inserts and turning tools

CNC grinding machine for precise grinding of interchangeable inserts made of HSS, carbide, PCBN or PCD with up to 1 radius

The Elite S2 is a CNC grinding machine for interchangeable inserts up to 1 radius

Control system with LCD screen and a numerical control axis for automatic grinding. High quality finishes with the best working times.

Its extreme ease of use makes it suitable both for the operator in the grinding shop and for on-site grinding in the production plants.

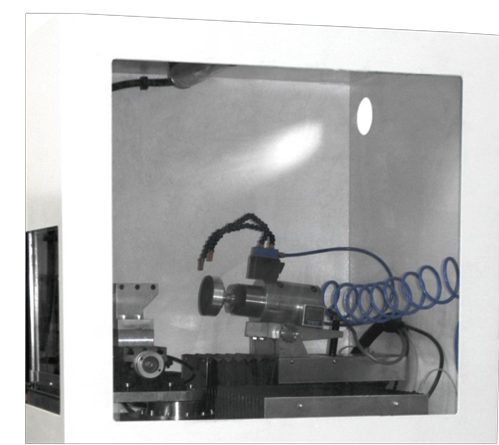

Wide field of view from the side panel

The full enclosure cabin of the S2 allows a good view of the working area from its side panel.

| Grinding wheel motor | 3 HP. Adjustable speed from 6000 to 12000 RPM by means of a frequency variator to adapt different wheel hardnesses |

|---|---|

| 3 automated axes by means of controlled motors | C, X and Y axes |

| A axis | +5º to -25º. For the selection of the tool's cutting angle |

| X2 axis | for tool positioning |

| Y2 axis | for tool positioning |

| Modificable data in software | X-axis travel speed. Number of grindings per tool from 1 to 9. Polishing pass for fine finishing. Grinding wheel motor speed. Grinding grinding wheel wear compensation cycle |

| 100 programs available | for the recording of work cycles |

| Automatic lubrication system | for spindles and guides |

Technical data

Available versions

| Model | Packing size | Weight |

|---|---|---|

| S2 Half enclosure | 1100 x 1300 x 1500 mm | 570 Kg |

| S2 Full enclosure | 1100 x 1300 x 2100 mm | 650 Kg |

HIGHLIGHTS

- Half enclosed machine, optionally available a full enclosed cabin

- Equipped with 3 CNC axes with controlled motors

- Programmable machine with LCD screen

- 100 programs available for recording work cycles

- Axis guides (X, Y) consisting of linear recirculating ball bearing slides on hardened and ground guideways

- Precision gearbox for the C axis

- Recirculating ball axis spindles

- Warning of the control of the recommended maintenance intervals.

- Automatic door safety system and emergency stop according to CE regulations.

Intuitive and very easy to use LCD control screen

With the guided data entry system, it is very quick and easy to program insert grinding values such as roughing cycles, tool angles and radius

Details that matter: Lighting by LED lamp

Allows for good lighting with low power consumption

Integrated cooling equipment

With a decanting system to keep the coolant clean for superior grinding quality

Optional accesories

- Tool holder for lathe tools

- Full enclosed cabin

Sharpening of an insert