We reserve the right to make design changes in the interest of technical progress.

www.elite.es

DOWNLOADS

SPECIFICATIONS

VIDEOS

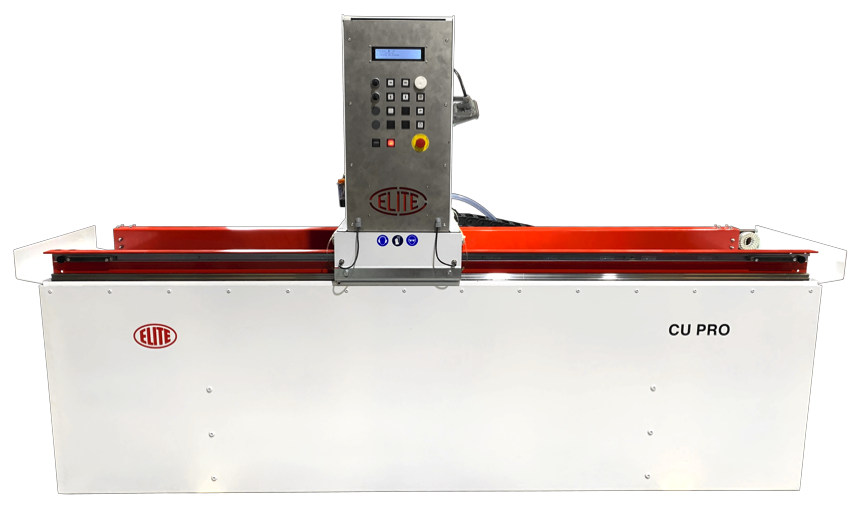

Industrial knife sharpening machine

Capacity up to 6150 mm. Depending on model

Automatic, simple, compact and economical machine which requires a low maintenance

Our ELITE CU PRO model is the most advanced manufacturing and sharpening knives machine. It features a grinding head designed to prevent corrosion better than standard painted grinding heads, equips a direct drive motor: this lets you have 20% more engine power compared to other engines that incorporates belt transmission.

Program your own sharpening parameters.

The control panel with LCD screen allows you to make and save programs easily, which it is perfect for sharpening and manufacturing knives either in series or in a timely manner thanks to its standard production program.

You can program a roughing cycle with its carriage speed, a finishing cycle with other parameters and speed, and an end cycle for polishing. All these operations are implemented by the machine at once.

¿Edge or against cutting edge sharpening?

Among of one of the programmable control parameters is the direction of rotation of the grinding wheel; say goodbye to tilt the head manually.

Easily access cooling equipment.

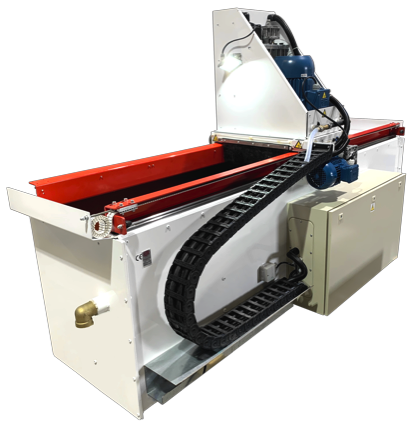

We thought that the cooling equipment must be easy to clean.Therefore, it can be mounted on the front of the machine or at the rear, or at the side, as best suits you!

Program your own sharpening parameters with the standard CNC panel. It allows to realize and to save programs, perfect for the sharpening of paper knives or knives manufacturing.

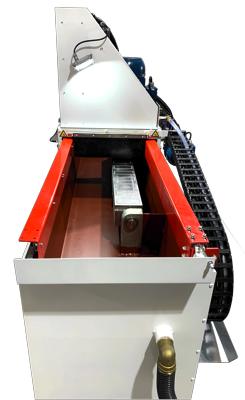

Magnetic knives chuck magnetizable and demagnetizable from the control panel. Same clamping force on the end of the plate or in the center: however narrow the knives are held perfectly on the edge of the plate. The strongest fixing on the market in knives sharpening machines. The super-polarity system is optionally available. With a fixing increased by 20%.

Ball screw in the vertical axis for a fluid movement and a down movement precision of 0.001 mm. The ball screw passes through the motor plate, guaranteeing maximum stability and rigidity and preventing dirt coming in from the sharpening.

Ball bearing for precise movement of the carriage, by ball recirculation with continuous lubrication system, allows a fluid movement without play and free of vibrations, because they hold the carriage so that it can not go down but not rise.

| Grinding wheel motor power | Direct drive 15 HP for 50Hz - 18 HP for 60 Hz - 1500 RPM |

|---|---|

| Grinding wheel diameter | 250 mm. (Optional 300 mm.) |

| Carriage speed | from 1 to 30 m/min. |

| Max. distance between grinding wheel and chuck | 180 mm. |

| Magnetic chuck wide | 150 mm. (Optional: 200 mm. and 250 mm.) |

| Coolant tank | 220 liters with mechanic separation |

| Max. connected power | 16 kW |

Technical data

Optional accesories

- Magnetic dust separator from coolant

- Grinding wheel motor 20 HP

- Grinding wheel motor 30 HP

- Secondary grinding wheel head with 5 HP motor

- XL grinding head, for heavy grinding or flat grinding of big surfaces

- Increased clamping force of the magnetic chuck (20% more force than standard)

- Magnetic chuck 200 mm. width

- Magnetic chuck 300 mm. width

- Grinding wheel ø300 mm.

- 4rth axe for knives toothing, includes control modification, ball bearing spindles and software

- Grinding wheel motor infinetely adjustable speed

Available versions

| Model | Size | Weight |

|---|---|---|

| 1000 mm. | 2200 x 1200 x 1800 mm. | 1090 Kg. |

| 1500 mm. | 2700 x 1200 x 1800 mm. | 1580 Kg |

| 2030 mm. | 3200 x 1200 x 1800 mm. | 2080 Kg. |

| 3060 mm. | 4200 x 1200 x 1800 mm. | 3080 Kg. |

| 4090 mm. | 5200 x 1200 x 1800 mm. | 4080 Kg. |

| 5120 mm. | 6200 x 1200 x 1800 mm. | 5100 Kg. |

| 6150 mm. | 7200 x 1200 x 1800 mm. | 6200 Kg. |

HIGHLIGHTS

- Very robust and powerful machine free of vibrations for more accurate and fast work.

- Greater precision in the Z axis, thanks to its operation by recirculating ball screw.

- Programmable by LCD display easy and intuitive to use.

- Carriage free of vibrations: movement by toothed belt

- Fully configurable operation cycle: roughing, finishing and polishing. Knives angle, grinding speeds, grinding loads and direction of rotation of the grinding wheel.

WORKING CONCEPT

Machine showed with optional XL grinding head

ELITE CU PRO