We reserve the right to make design changes in the interest of technical progress.

www.elite.es

DOWNLOADS

SPECIFICATIONS

VIDEOS

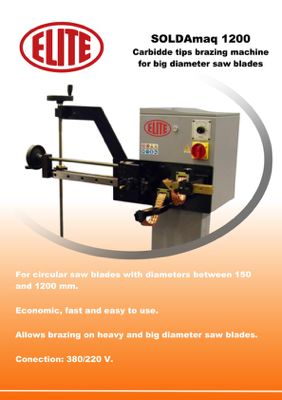

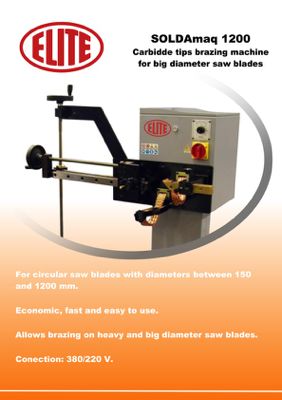

For circular saw blades with diameters between 150 and 1200 mm (5,9" up to 47")

Economic, fast and easy to use.

Allows brazing on heavy and big diameter saw blades.

The ELITE SOLDAmaq 1200 is specially designed for its dimensions for sawmill industry but is suitable for every type of carbide tipped circular sawblade.

For the repair or manufacture of carbide tipped circular saw blades.

Easy, economical and fast to use.

It is possible to braze every tip profile

| Saw blade diameter | from 150 to 1200 mm (5,9" to 47"). |

|---|---|

| Saw blade hole | from 20 to 130 mm (0,78" to 5-1/9") |

| Brazing angle | from -20º to +25º |

| Installed power | 4 kW |

Technical data

Available versions

| Model | Packing size | Weight |

|---|---|---|

| SOLDAmaq 1200 | 810 x 920 x 1600 mm | 90 Kg. |

HIGHLIGHTS

- Linear guides with recirculating balls for saw adjustment

- Infinitely adjustable potentiometer for welding / desoldering temperature control

- Two spindles for effortless adjustment of saw diameter and tooth angle

- Extremely simple operation by means of a single potentiometer button, which regulates both the start of the welding and the power to be applied

- Highly rigid machine designed to operate for many years without the need for maintenance.

High quality components for long lifetime

MANUAL

Working concept

WELDING:

1. Place the saw in the saw holder of the machine

2. Place the new TCT in the socket and position the saw on the tooth

3. Press the welding button

Repeat this process as many times as you want to weld and you will have the saw finished and ready to sharpen.

UNWELDING:

1. Place the saw in the saw holder of the machine

2. Support the saw with the tablet you want to remove in the housing

3. Press the welding button, the tooth is heated and with one of your two free hands you can remove it with the help of a rod so as not to burn yourself