We reserve the right to make design changes in the interest of technical progress.

www.elite.es

DOWNLOADS

SPECIFICATIONS

VIDEOS

Technical data

ELITE FILTRAmaq PRO

Filtration of coolant for up to 5 machines

It can be used both with oil and with oil in emulsion.

Filtration flow rate: up to 200 l / min.

Filtration quality down to 2 µm

Available with automatic coolant chiller system

The new ELITE FILTRAmaq PRO, is our autonomous equipment for the filtration and cooling of liquids, up to 2µm. It represents a renewed and improved version of the previous model.

- The filtration system is very affordable in size/quality.

- Low maintenance cost.

- Available with nominal filtration flow rates of 50 l/min, 100 l/min, 150 l/min and 200 l/min.

- Coolant chiller system available as an option.

- Customers can now use high quality sharpening oils such as our SintoCut PRO MD synthetic oil: combined with our filter systems, they will never have to change the oil again, they will simply have to refill the oil lost during normal work.

- The useful life of the grinding wheel increases up to 4 times.

- The surface roughness of the cutting tools is improved, especially when dealing with a hard material such as tungsten carbide. This makes your tools more competitive.

| Filtration flow rate | 50l/min. Optionally available in 100 l/min., 150 l/min. and 200 l/min. |

|---|---|

| Filtration quality | 2µm |

| Connection to the sharpening machine | Return to filter by gravity. 2" filter inlet. Sending coolant through the own pump of the grinder installed in the filter. |

| Automatic filling of the filtration tank | Selectable automatic tank refill. In the case of oil emulsion filling, the mixture can be selected from 1% to 5%. In the case of filling with oil, the oil tank must be at a height higher than that of the filter. |

| Chiller System for coolant | Optionally available with selectable temperature regulation between 15ºC to 30ºC |

| Filter control | With LCD display, indication of working hours, automatic refilling system and clean and dirty coolant levels |

Optional accesories

- Additional filtration unit: adds 50 l/min of filtration capacity for each additional unit, up to a maximum of 200 l/min of total filtration flow rate capacity.

- Chiller to mantain the coolant temperature stable. Cooling capacity: 5kW

Dimensions and weight

| Model | Size | Weight |

|---|---|---|

| FILTRAmaq PRO without chiller | 1300 x 900 x 1700 mm. | 460 Kg. In running order |

| FILTRAmaq PRO with chiller | 1300 x 900 x 1900 mm. | 520 Kg. In running order |

HIGHLIGHTS

- High quality 2 µm filtration

- Gravity refrigerant return system: Energy savings of up to 50% due to the fact that a return booster pump is not necessary

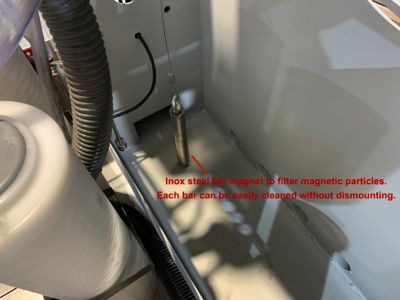

- Dirty coolant pre-cleaning system using powerful neodymium magnets coated in stainless steel, very quick and easy to clean.

- Possibility of filtering up to 5 machines, depending on the pumping flow of the machines.

- The optional cooling system is integrated inside the machine, thus saving space.

- Very high filtering flow: up to 200 liters per minute

- Grinding accuracy is improved: by filtering and cooling/heating the coolant, tolerances due to thermal expansion are eliminated

- Compact machine shape ideal for placement between machines

Control panel with LCD screen

With information on the time of use, clean and dirty coolant level, and activation of the automatic tank refilling system

Working principles

Dirty coolant inlet

Pumping of the clean liquid by means of the pump of the sharpening/grinding machine itself.

Very easy to change filter cartridge system.

Dirty and clean liquid level sensor to control the status and flow of the coolant and decide if the filter tank should be filled automatically.

Stainless steel bars with neodymium magnets to remove magnetizable particles, thus saving on filter cartridge consumables.

The bars are very easily accessible to easily remove dirt.

View of the filtration system with the cooling system mounted (Available as an option).