We reserve the right to make design changes in the interest of technical progress.

www.elite.es

DOWNLOADS

SPECIFICATIONS

VIDEOS

CNC grinding machine for carbide tooth sides equipped with cooling

Double wheel system

For the manufacture or repair of circular saw blades with tungsten carbide teeth.

The ELITE model GBT 850 DUO is our CNC grinding machine for the flanks for circular saws with tungsten carbide teeth.

This version is equipped with double grinding wheel and its operation is CNC with LCD screen. It allows a precise and fast grinding of the flanks of the teeth to manufacture carbide circular saws or carry out teeth replacement

| Saw blade diameter | from 100 to 850 mm (from 4" to 33.5") |

|---|---|

| Saw blade hole diameter | From ø10 mm. |

| Sheet thickness | Up to 10 mm. |

| Tooth pitch | From 1 to 125 mm. |

| FLANK GRINDING | |

| Sharpening path | Up to 40 mm. |

| Rake angle | From -15º to +30º |

| Radial cutting angle | From -5º to +6º |

| Tangential cutting angle | From 0º to 8º |

| REFRIGERATION EQUIPMENT | |

| Reservoir capacity | 220 liters |

| Coolant flow rate | Up to 40 liters/minute |

| TECHNICAL DATA | |

| Automation | Using 4 CNC axes (X, Y1, Y2, A) |

| Clamping the saw | By pneumatic piston |

| Motor wheel | 0.75 kW (each unit) |

| Wheel speed | adjustable from 5000 to 9000 RPM |

| Diameter of grinding wheel | ø100 mm. |

| Diameter of grinding wheel hole | ø20mm. |

| Dimensions of the machine | 1410 x 1225 x 1800 mm. |

| Connection | 230V/400V, 50/60 Hz. Total connected power: 3.3 kW - Requires a pressurized air supply >6 Bar |

| Machine weight | 840 Kg. |

HIGHLIGHTS

- Any pitch of the tooth is possible

- Integrated refrigeration equipment

- Robust and very simple design that allows continuous use of the machine without breakdowns

- Easy to use

- Very compact machine with a wide range of disc diameters: from 100 to 850 mm.

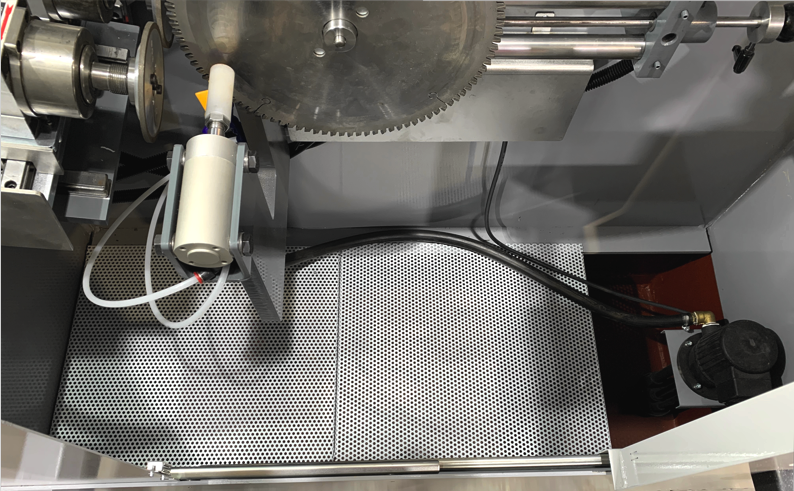

Integrated refrigeration equipment

Allows wet sharpening for better sharpening quality and longer life of the sharpening stone.

It integrates a 200-liter tank with removable grids for easy cleaning.

ELITE GBT 850 DUO

Saw diameter from 100 mm.

For grinding the flanks of scoring discs or portable machines.

Allows indexing of any type of tooth pitch.

Control panel of simple and fast use

The machine includes a led cabin light as standard.

The control panel allows selection of left or right rotation of the sharpening stone.

The grinding wheel motors with a direct motorized spindle system are adjustable from 5,000 to 9,000 RPM for optimum sharpening quality with minimal stone wear. It is driven by a frequency inverter.

Easy access

Clean design and easy access for service or repair of the machine.

The electrical panel is located at the bottom and the mechanics at the top of the machine, protected by an easy-to-open cover.

| Model | TOP GRINDING | FACE GRINDING | BACK OFF GRINDING | SIDES GRINDING |

|---|---|---|---|---|

| AVB 850 | All tooth shapes | All tooth shapes | NO | NO |

| SVG 850 | All tooth shapes | Flat teeth | YES | NO |

| MD | All tooth shapes | All tooth shapes | NO | NO |

| MVB 850 | All tooth shapes | Flat teeth | NO | NO | MD mini | Flat teeth | Flat teeth | NO | NO |

| GBT 850 mono | NO | NO | NO | One side at a time |

| GBT 850 DUO | NO | NO | NO | Two sides at a time |

| GBT 851 DUO | NO | NO | NO | Two sides at a time |

General machine description

Programming and operation of the machine

Homing of the axis